Transitioning from coaly residues to eco-friendly plastic sorting processes

Plastic Waste Transformed: Umweltdienste Kedenburg's Circular Economy Revolution

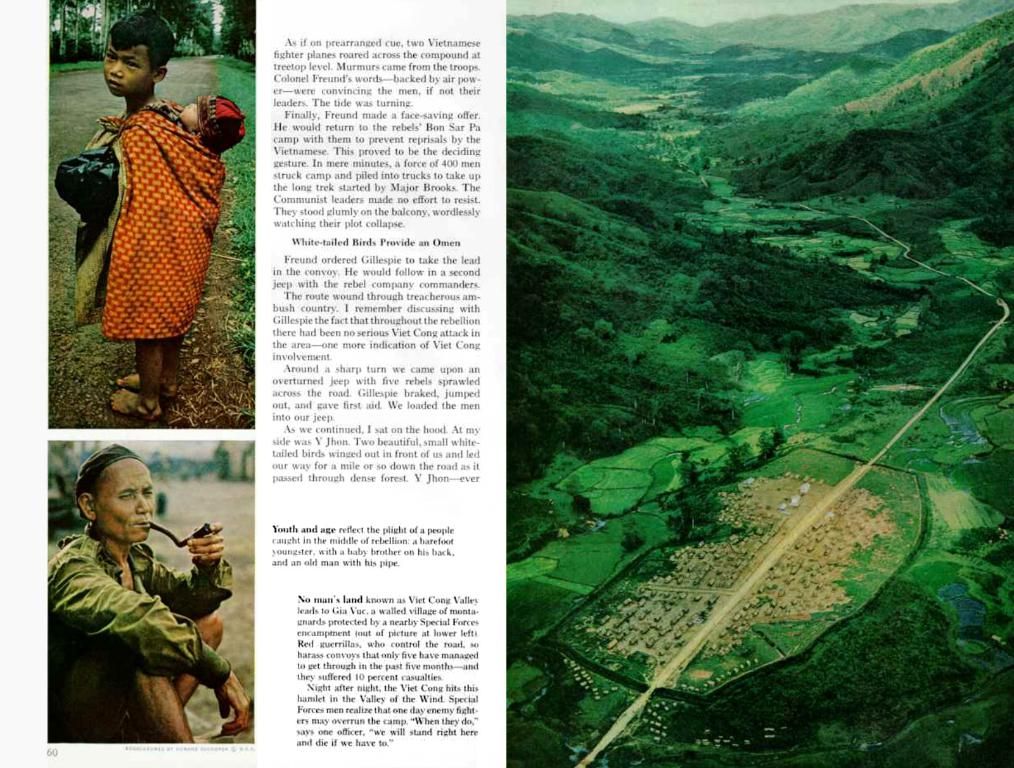

Ten years ago, Umweltdienste Kedenburg breathed new life into Beckum's industrial wasteland, once a hub for cement production and coal storage. Today, this site serves as a production hub for recycled plastic materials, a testament to the power of the circular economy. Klaus Kuhlenbeck, the facility's Technical Director, considers it an investment in the future, with a clear goal: ensuring top-notch plastic films are sorted and prepared for transformation into new products.

From Trash to Treasure

In partnership with Otto Graf GmbH, a cutting-edge sorting facility was established to process films from mixed lightweight packaging. The facility primarily processes polypropylene (PP) films, with the remainder being polyethylene (PE) or a mix of polyolefins (PO). Most of these materials originate from pre-sorted facilities across Europe, spanning countries like Austria to Norway.

Technology's Role in Triumph

At the heart of the facility stand two STEINERT UniSort Film EVO 5.0 machines. These machines excel thanks to a specific airflow system that seamlessly synchronizes with the conveyor speed. Kuhlenbeck praises the directed, stabilized airflow for keeping even the lightest, most flexible films steady on the conveyor. The airflow's precision extends beyond the ejection box, minimizing material swirl after ejection. In the expert's opinion, the UniSort Film is the market's most formidable solution to meet the facility's requirements.

This excellent material guidance enables a swift conveyor speed of 4.5 m/s, essential for achieving high throughputs and profitable sorting with bulky 2D materials. Plastic films avoid overlap or turning over, allowing the combination of near-infrared (NIR) sensors and color cameras to function optimally. This precise data capture is vital for ensuring the targeted purity of 98% for PP films.

Quality Plastic Films from Secondary Materials

Once sorted, the films undergo agglomeration; they're compressed by heat and friction to create manipulable granules. These intermediate products are then purified of the slightest ferrous and non-ferrous particles using a combination of STEINERT MOH with EddyC FINES magnetic separators. The plastic agglomerates are then sent directly to GRAF for production of durable items like rainwater tanks. Customers enjoy products that are not only long-lasting but also of unwavering quality, equal to that of new goods.

Preparing for the Future

Kuhlenbeck stresses the importance of future-proof investment: "Our facility is designed to adapt to changing demands. We understand that packaging materials evolve over time. With the combination of NIR and color sensors, we can accommodate future advancements."

For Kuhlenbeck, the installation is never truly complete. Challenges such as composite materials and aluminum-metallized films with hidden components require constant vigilance. Open dialogue throughout the value chain is essential: "We've moved beyond individual efforts. Through collaboration, we're strengthening recycling, developing better packaging, and pushing for a more sustainable, circular economy."

Confidence Inspired by Testing - Durability is our Goal

Kuhlenbeck's journey with STEINERT commenced in the company's test center located near Cologne. Achieving milestones crucial for the project's success took place there as early as 2023. "From the outset, STEINERT met our expectations flawlessly. I've never seen such reliability—exactly what we need for our vision of sustainable plastic recycling," Kuhlenbeck summarizes. With the installation in Beckum, a former CO2 emitter is transformed into a beacon of sustainable development. Every kilogram of plastic recycled allows Umweltdienste Kedenburg to contribute actively to climate protection, reduce CO2 emissions, and conserve natural resources.

In the quest for a world of infinite resources, Umweltdienste Kedenburg exemplifies how innovation, technology, and collaboration can create a cleaner, greener future.

- In the pursuit of sustainable living and environmental-science, Umweltdienste Kedenburg's partnership with Otto Graf GmbH and the use of STEINERT UniSort Film EVO 5.0 machines aim to transform plastic waste into new, high-quality products, contributing to a circular economy in the home-and-garden and lifestyle sectors.

- As a testament to Umweltdienste Kedenburg's dedication to climate-change mitigation, their facility processes recycled plastic films, primarily polypropylene (PP), to create durable items like rainwater tanks promoting a sustainable, circular lifestyle.

- With an eye on the future, Klaus Kuhlenbeck, Technical Director at Umweltdienste Kedenburg, underscores the importance of advancements in environmental-science and technology to adapt to evolving packaging materials, collaborate within the value chain, and continuously pursue a more sustainable world.